VEC Implementation Guidelines

The VDA recommendation 4968 / prostep ivip recommendation PSI21 “Vehicle Electric Container (VEC)” defines an information model, a data dictionary, a XML schema and a RDF onthology derived from and compliant to the model.The intention of the model was to cover a wide range of use cases and application scenarios. For this reason the specification had to be kept generic in some degree and in some aspects. However, for specific scenarios and / or use cases a more detailed description on “how the different pieces fit together” is possible.

To avoid dialects in the different VEC implementations, further guidelines or recommendations are necessary. This collection of implementation guidelines contributes to the unambiguous interpretation of the VEC standard. For various wiring harness definition or electrical system aspects and scenarios the correct instantiation is shown and specific hints for correct usage are given.

Contributing and Proposals

If you find any bugs in the implementation guidelines or if you have a request for a specific topic, or if you would like to contribute your own tutorials please drop us an issue on the GitHub Issue Tracker. For more information please read our “Contribution Guideline”.

Additional Resources

Latest Changes

The following table contains lately changed pages, sorted descending by last change.| Title | Latest Content Addition / Commit | Created | Changed |

| Tapes and Tubes | #913: Initial version, specifically addressing the utilization of ProtectionGroups Latest Commit: Added a full page for tapes & tubes and explaining specifically the wireprotectiongroup (#956) | 2026-01-28 | 2026-01-29 |

| General Structure of VEC Files & Documents | #956: Added section on 'Content from mixed Sources' Latest Commit: Added section about content from mixed sources (#956) | 2020-06-22 | 2026-01-28 |

| Placements and Dimensions | Clarified semantic difference between SegmentLocation and NodeLocation. Latest Commit: Complete rework of wire protections after clarification of Node- & SegmentLocations (#935) | 2019-03-11 | 2026-01-28 |

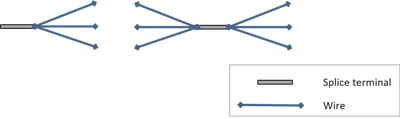

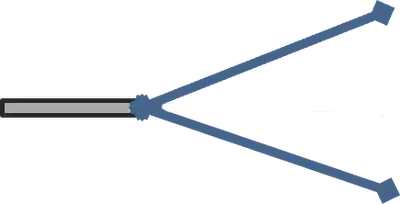

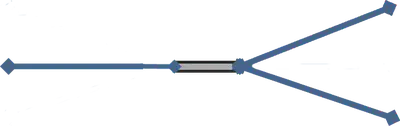

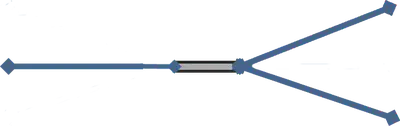

| Splices | KBLFRM-855: Splice: Number of wires from the left / number of wires from the right Latest Commit: Complete rework of wire protections after clarification of Node- & SegmentLocations (#935) | 2022-11-09 | 2026-01-28 |

| Files, Partitioning, Sizing & Packaging (XML) | #1144: Added recommendation for file extension and IANA Media Types of VEC files. Latest Commit: Removed review note as decided in meeting 2026-01-16 | 2024-03-14 | 2026-01-23 |

| Instances of Components | #484: Added example for PartSubstitutionSpecification Latest Commit: Removed review note as decided in meeting 2026-01-16 | 2022-10-07 | 2026-01-23 |

| Topological Protection Requirements | #1138: Added guideline for topology zone requirements. Latest Commit: Removed review note as decided in meeting 2026-01-16 | 2025-12-08 | 2026-01-23 |

| Product Definition of a Harness | #1036: Content of a HarnessDescription Latest Commit: Clarified some passages. | 2022-09-01 | 2026-01-23 |

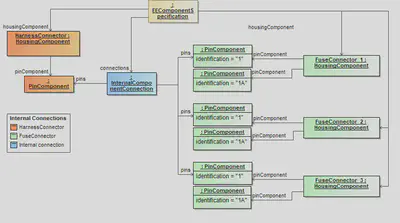

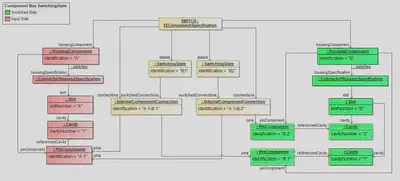

| Internal Connectivity | #915: New generic concept for E/E component with internal connectivity. Latest Commit: Removed review annotations. | 2025-07-08 | 2025-12-08 |

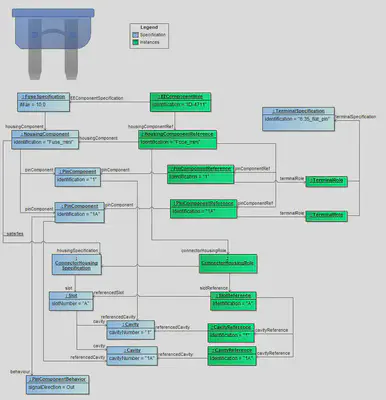

| Connectors | #957: Improved cavity mapping for modular connectors. Latest Commit: Removed review annotations. | 2018-11-29 | 2025-12-08 |

General Guidelines

This section contains guidlines and explanations for general concepts that apply universally to the VEC and which are not limited to specific model elements or use cases. Therefore they not contained in the model specification, or in more specific implementation guidelines. These guidelines shall be followed for all VEC implementations.

XML / XSD Representation

Mapping of UML VEC Model to XML Schema Definition (XSD)

The mapping of the VEC model to an XML schema definition (XSD) described in the following defines the standardized syntax for the exchange of harness design data across process steps and supporting tools.

The dedicated namespace prefix of the schema definition is vec, the namespace is http://www.prostep.org/ecad-if/2011/vec.

The XSD defines a single VecContent-element as xs:element. This is the declared root element for all VEC compliant XML-documents. A VEC compliant XML-document is limited to one instance of a VecContent.

Classes

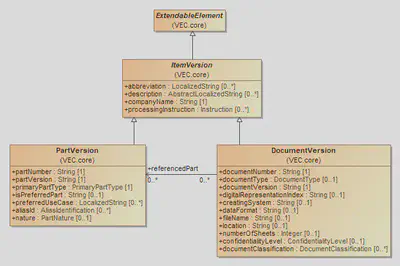

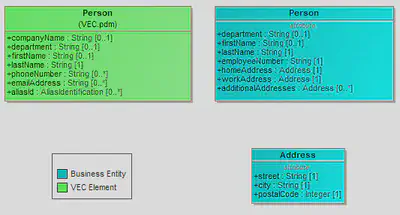

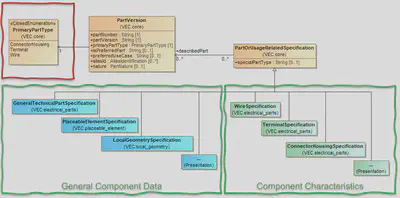

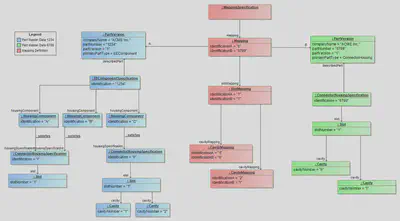

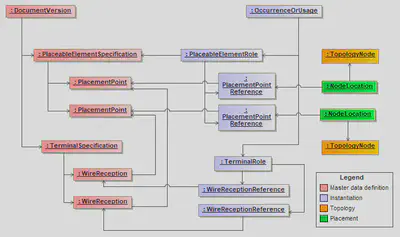

Each VEC UML model class (see figure below for an example from the VEC), which is not stereotyped as <<enumeration>>, are mapped in the following form.

- Each regular UML class is mapped to a

xs:complexTypewith the same name as the VEC model class name. - If the VEC model class is a derived subclass the corresponding

xs:complexTypedefines axs:extension. - VEC model class attributes & associations which are defined by the class itself and not inherited, are mapped to a

xs:sequenceofxs:elementswith the same names as the names of the corresponding class attributes (see Attributes and Associations below).

<xs:complexType name="DocumentVersion">

<xs:complexContent>

<xs:extension base="vec:ItemVersion">

<xs:sequence>

<xs:element name="DocumentNumber" type="xs:string"/>

<xs:element name="DocumentType" type="vec:DocumentType" minOccurs="0"/>

...

<xs:element name="DocumentClassification"

type="vec:DocumentClassification"

minOccurs="0"

maxOccurs="unbounded"/>

<xs:element name="ReferencedPart" type="xs:IDREFS" minOccurs="0"/>

...

</xs:sequence>

</xs:extension>

</xs:complexContent>

</xs:complexType>

Identifiers

id-Attributes

All xs:complexType that are not a refinement of another type (via xs:extension) define a mandatory XML attribute id with the type xs:ID. Syntax restrictions and uniqueness constraints for xs:ID are defined by the XML standard itself. xs:ID values are required to be unique within a XML document. Assocations between objects within a VEC XML document are defined with the help of xs:IDREF(S). The values in a xs:IDREF(S) must be defined xs:ID values existing in the context of the document.

The values for the id-attributes are normally generated by exporter / XML processor during the XML file generation. Exporters are expected to generate valid values for the id-attributes so that Links (instances of associations) are expressed correctly and the resulting XML file is XSD compliant.

<xs:complexType name="ExtendableElement" abstract="true">

<xs:sequence>

...

</xs:sequence>

<xs:attribute name="id" type="xs:ID" use="required"/>

<xs:attribute name="immutable-global-iri" type="xs:anyURI"/>

</xs:complexType>

id-attributes have temporary character. By this recommendation exporters are not required to remember values they have once created during an export. Exporters are explicitly allowed to assign different values for the id-attributes during every export process.immutable-global-id-Attributes

As defined in the section above, each xs:complexType defines a XML-Attribute id with the type xs:ID, either by itself or by inheritance from a superclass. By nature, those ids are volatile and have a purpose only within a specific XML file.

However, there are requirements in advanced use cases where it is necessary to be able to identify objects in the VEC globally and in a temporally stable manner. Such use cases are for example, but not limited to:

- Change Management & Synchronization

- Integration with other Standards, e.g. the Asset Administration Shell (AAS)

- Provision of VEC objects via modular APIs (e.g. REST)

- Compliance with other serialization formats like RDF.

Therefore, each xs:complexType that defines an id-attribute also defines an immutable-global-iri attribute with the type xs:anyURI. Despite its name xs:anyURI is in fact the type for an Internationalized Resource Identifier (IRI), see “W3C XML Schema Definition Language (XSD) 1.1 Part 2: Datatypes”.

If two VEC objects, regardless of their context or their affiliation to a specific file, have the same immutable-global-iri, they are in fact a representation of the same (real world) object (potentially in a different state).

The concept of IRIs allows the definition of global unique identifiers in various ways and with different strategies. For example, using http-IRIs allows the dereferencing (finding) of objects identified by such IRIs. However, the chosen strategy has a strong influence on the circumstances under which two objects in the VEC can be identified as the same. Both effects (same & not the same) can be desired effects in a specific use case / process / scenario. Therefore, this recommendation does not define a specific strategy for minting IRIs for VEC objects. It is also beyond the scope of this recommendation to describe or define valid strategies for minting IRIs.

However, two examples shall illustrate the influence of a choosen strategy. The examples are for illustrative purposes only and their description does not claim to be complete:

- UUIDs: IRIs can be created from UUIDs. UUIDs are generated random values that guarantee universal uniqueness. To satisfy the requirement of temporal stability, a source system has to maintain (store) those UUIDs for every object. Objects that are created and distributed at the same time in different locations are hard to handle. Objects deleted from the system (and then recreated) are always handled as different objects.

- Calculated IDs: IDs could be calculated from object keys in the domain (e.g. the identifying attributes of a

PartVersion). Such IDs could be calculated on the fly and do not have the requirement to be stored along with the object, as they are stored implicitly via the attributes from which they are derived. If the same object (same identifying attributes) is created in different locations, both variants can still be recognized as identical. On the downside, an ID generation algorithm has to be defined, that generates those unique IDs for every possible object type and situation. The algorithm has to guarantee that the generated IDs fulfill uniqueness requirement, which depends on the naming / identification strategy of the process. And yet, there are still cases where objects can not be recognized as the same (e.g. renaming of “key”-attributes).

Attributes & Associations

In the XML Schema represention of the VEC, attributes and compositions are handled in the same way. The containing (or orginating) class defines a xs:element. The name-attribute of the xs:elementis equivalent to the name of the attribute or the target role in the UML model. The first letter is converted to upper case. The type of the xs:element is either a primitive type (see mapping below) or a reference to corresponding VEC schema type.

All associations in the VEC model are directed and therefore have a defined source and target. An association is mapped to an xs:element which is owned by the XSD complex type that represents VEC model class that is source of the association. The name of the element is equal to the name of the association target role name (first letter upper case). The type is xs:IDREF respectively xs:IDREFS depending on the associations target cardinality.

xs:IDREF(S) does not ensure typesafety of assocations. Meaning, that the only enforced constraint for values of a xs:IDREF(S)-elements by XML Schema is, that the value must be defined as an xs:ID somewhere within the document.

So any association pointing to any object within a VEC XML document will successfully pass a schema validation. However, it might violate type constraints imposed by the underlying UML model, resulting in a document not being VEC compliant, despite that fact that it is schema valid.

Primitives

The UML uses sereval primitive data types that are mapped to the correspondig XSD data types:

xs:string(corresponding to the VEC model data type definition String)xs:dateTime(corresponding to the VEC model data type definition Date)xs:integer(corresponding to the VEC model data type definition Integer)xs:double(corresponding to the VEC model data type definition Double)xs:boolean(corresponding to the VEC model data type definition Boolean)

Meta Model annotations embedded in XML Schema

Due to the nature of XML Schema and XML files it is not possible to express all specifications, restrictions and additional information of the VEC model (defined as UML model) directly in XML Schema. In particular, these are:

- Target types for

IDREF/IDREFSassociations, - Uniqueness of collections (bag vs. set semantics),

- Ordering of collections,

- Assignment of model elements to packages / namespaces in the model, and

- Deprecation of model elements.

To overcome this gap, additional meta information, embedded in the XML Schema will be provided for future versions (Version > 2.0.1). The extension is done with the annotation concept provided by XSD (xs:annotation / xs:appinfo see W3C XML Schema Definition Language (XSD) 1.1 Part 1: Structures / 3.15.1 The Annotation Schema Component).

The XSD schema for the content of the xs:appinfo can be downloaded here:

model-meta-1.0.0.xsd

. The XML target namespace of the meta information is: http://www.prostep.org/ecad-if/2022/model-meta .

Package

All types defined in the VEC are associated with a namespace, e.g. core, electrical_parts, schematic. This meta information is defined as follows:

<xs:element name="package" type="meta:Package"/>

<xs:complexType name="Package">

<xs:attribute name="name" type="xs:string"/>

</xs:complexType>

Deprecation

In case a model element (class, attribute, association, enumeration, literal etc.) gets deprecated, it will be annotated with deprecated along with further information about the reason for deprecation and the VEC version since when the deprecation is in place. Normally deprecated elements will be removed with the next major release.

<xs:element name="deprecated" type="meta:Deprecation"/>

<xs:complexType name="Deprecation">

<xs:attribute name="reason" type="xs:string"/>

<xs:attribute name="since" type="xs:string"/>

</xs:complexType>

Collections

Meta information for associations / collections is defined as follows:

...

<xs:element name="relationship" type="meta:Relationship" />

<xs:simpleType name="RelationshipType">

<xs:restriction base="xs:string">

<xs:enumeration value="Attribute" />

<xs:enumeration value="Association" />

<xs:enumeration value="Composition" />

</xs:restriction>

</xs:simpleType>

<xs:complexType name="Relationship">

<xs:attribute name="element-type" type="xs:QName"/>

<xs:attribute name="relationship-type" type="meta:RelationshipType" use="required"/>

<xs:attribute name="unique" type="xs:boolean" default="true"/>

<xs:attribute name="ordered" type="xs:boolean" default="false"/>

</xs:complexType>

...

All elements in the model that are defined as an association, with or without composition, and all attributes receive a relationship annotation. Regarding the XML Schema alone, attributes and composite associations have a similar XSD definition. However, the modelling approach in VEC was chosen intentionally and there are subtle differences in semantics in the context of the specification.

The attribute representation is used for primitive types and structured value types (e.g. NumericalValue, Material or Color). Those elements do not have complex substructures and do not have incoming associations. On the other hand, composite associations are used for more complex substructures and elements that are relevant in a larger context (e.g. Slot, Cavity or WireElement).

element-type: The schema type of elements referenced by the association as defined in the UML model, to preserve type info forIDREF(S), which will be lost otherwise in native XML schema. Only allowed onIDREF(S)elements.relationship-type: The type of the relationship as defined in the UML model.unique: Defines the collection semantics for elements referencing more than one element.unique=falsemeans that the model allows duplication for this reference. In other words, the same object can be referenced multiple times (bag semantics).unique=trueapplies when an element should only be referenced once (set semantics). Composite associations can only beunique=true.ordered: Defines that the order of the collection has a semantic meaning and is not just given, because XML is an ordered format by definition.

The attributes of the relationship element are only present if the attribute has a reasonable, non-redundant meaning in the context. ordered or unique for a 0..1 association has questionable value, unique for composites can only be true and element-type is only relevant for IDREF(S) associations, because for composites the information is already contained in the regular schema definition.

Tailoring Concepts

Motivation and Objective

The VEC provides a comprehensive model for the digital description of a wide variety of information and their relationships to each other in the context of the electrical system development process.

Despite the striving for the greatest possible semantic precision, the demand for general applicability of the standard means that, at various points restrictions cannot be formulated to the same extent as it would be possible in the context of a very specific use case or a company context. This applies to the following examples, among others:

- The set of valid model elements: Probably no use case requires all 450+ classes of the VEC at the same time and the set of required model elements is highly dependant from the use case itself.

- Valid values for attributes: The allowed patterns and / or discrete values (enumerations) of attributes can depend on a specific use case or company context and can even change over time (e.g. new technologies)

- The balance between mandatory and optional information: The amount and completeness of information contained in a VEC depends on the use case and process. While it might perfectly ok the have some missing information in an early phase of the process, it might intolerable at a later stage.

This implementation guideline presents three approaches for adapting the XML representation of the model to address the above issues in specific application scenarios, while still maintaining compatibility with the standard:

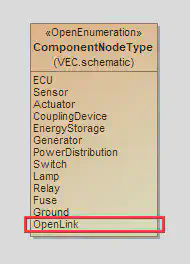

- Custom Open Enumerations: New literals can be added to open enumerations (see Open and Closed Enumerations)

- XSD 1.1. Assertions: The schema can be enriched with assertions to be more restrictive.

- Schema Filtering: With “Schema Filtering” the schema can be made less extensive and by this also more restrictive (Less allowed classes, attributes etc.).

All these approaches have in common, that the schema of the standard is adapted / modified in a suitable form. The result is a tailored VEC XML Schema that is specific for the use case, but still compatible with the regular VEC schema.

This Implementation Guideline explains how these modifications can be achieved in an efficient way based on XSLT. XSLT is a useful technology, when:

- you want to modify XML data,

- you can define the modification based on rules,

- the general structure of your result is close to the input,

- and performance is not critical.

This makes it the perfect solution for this use case, where we want to modify the XML Schema of the VEC at very specific locations while keeping the rest unchanged.

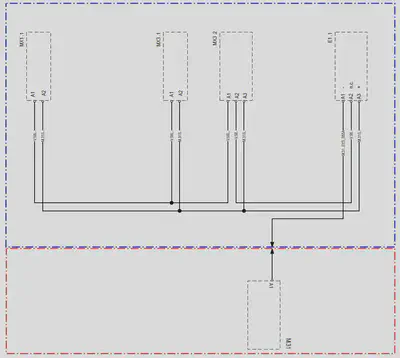

General Concept

The general concept is illustrated in the figure above. The customization rules are defined in an “compiler XSL-file”. This file defines how the extensions are defined syntactically in the schema. It compiles the customizations into an existing schema. For example, in case of open enumerations, the compiler file defines at which position in XSD new literals have to be inserted. The compiler files are universal and independent of the specific context (e.g. company, use case) of the customization. For open enumerations and assertions such compiler files are provided here.

The actual customizations are defined in an external XML data file (Customization Definition in the figure above). For example, in case of open enumerations, the data file defines which enumerations should be extended with which literals. This information is specific to the customization context and has to be created during the customization process. The syntax of the data file depends on the compiler file, but is usually trivial.

To create a custom VEC schema, the desired schema variant (strict or not) of the underlying VEC version is passed into a XSLT transformation pipeline, with the Compiler XSL as transformation. The data file is side loaded from the Compiler XSL.

Run the Transformation

java -cp /path/to/saxon.jar net.sf.saxon.Transform \

-xsl:./path/to/compiler.xsl

-s:/path/to/vec.xsd

-o:/path/to/result.xsd

data-file=url-to-data-file.xml

If the url-to-data-file.xml is a relative path, then it is relative to the compiler.xsl. The easiest way is to place required files (including the data file) in the current working directory.

Open Enumerations

Open Enumerations are a concept in the VEC to have predefined values for attributes, whilst being open for extension (for details see the corresponding recommendation chapter Open and Closed Enumerations). Two schema variants are provided officially for the VEC: the regular and the strict schema. The regular schema can be used for pure syntax validation of VEC files. However, it makes no restrictions for the use of values in attributes with an open enumeration type. The strict schema restricts these attributes to have only values that are defined literals from the VEC standardization board in the corresponding open enumeration. The advantage of using the strict schema is that you are able to validate that only defined literals have been used.

However, if you extend1 an open enumeration with new literals, e.g. for your process specific requirements, or new wiring harness technologies, then the strict schema validation will break. In this case it is not possible anymore to check if only defined values, either by the standard or the process, have been used. Nevertheless, it would be highly appreciable to still have such a mechanism in place. To achieve this, you need an extended strict schema, that includes the values from the standardization board and the process specific values. This implementation guideline is about creating such an extended strict schema.

What you need

The generation of such an extended strict schema is done as described in section General Concept. As input, you need:

- The Compiler XSL: vec-open-enum-compiler.xsl

- A definition of your enumeration extensions, an example can be found here: enum-literals.xml

Define new Enumerations

The enum-literals.xml (link above) file contains examples on how to add custom enumerations.

<?xml version="1.0" encoding="UTF-8"?>

<enum-profile>

<enum type="WireReceptionType">

<literal name="MyExampleLiteral">

My example description with html elements <br/>

</literal>

<literal name="MyExampleLiteral2" />

</enum>

<enum type="WireLengthType">

<literal name="MyExampleLiteral3">

My second example description

</literal>

</enum>

</enum-profile>

This example adds a literal with the name MyExampleLiteral to

WireReceptionType with a description (Note that it is possible to include html

tags) and a literal without a description named MyExampleLiteral2. It also

adds MyExampleLiteral3 to WireLengthType.

If a new VEC version is released, this file can be used recreate an updated company specific scheme (without having to repeat all changes manual).

Schema Assertions

XSD 1.1 introduced a concept to define Assertions within a XSD:

An assertion is a predicate associated with a type, which is checked for each instance of the type. If an element or attribute information item fails to satisfy an assertion associated with a given type, then that information item is not locally valid with respect to that type.

Assertions are defined as XPath 2.0 expressions that are evaluated to true or false. This makes it possible to express much more meaningful rules in the schema than it is possible with the pure syntax checking of XSD 1.0. In particular, it is not only possible to further restrict the multiplicities of attributes, but more complex conditions, such as dependencies between attributes, can be expressed (e.g. like “if type is ‘rectangle’ then count(sides) must be greater equal 4”).

The great benefit of this approach is, that these rules are validated during a regular schema validation with a standard XML Parser.

descendant nodes (see XPath Axes) of the context node can be used in the XPath expression. Functions like .., id() or idref() are not available.What you need

The generation of such an asserted schema is done as described in section General Concept. As input, you need:

- The Compiler XSL: vec-assertions-compiler.xsl

- A definition your custom assertions, an example can be found here: data-profile.xml

Define Assertions

The data-profile.xml (link above) file contains examples on how to add custom assertions.

<?xml version="1.0" encoding="UTF-8"?>

<data-profile>

<context type="ConductorSpecification">

<rule test="CrossSectionArea">

All conductors shall specify a cross section area. The cross section area is an

important parameter for numerous design rules (e.g. aggregated cross section area

of splices).

</rule>

<rule test="CrossSectionArea/ValueComponent gt 0.0">

A conductor with cross section area not greater than 0 is non-existent.

</rule>

</context>

<context type="CavityAddOn">

<rule test="WireAddOn/ValueComponent gt 0.0"/>

</context>

</data-profile>

context type="..." defines the VEC class to which an assertion should be added. rule test="..." defines the XPath expression of the assertion that should be added to corresponding type. The above data-profile results in the following XSD:

<?xml version="1.0" encoding="UTF-8"?>

...

<xs:complexType name="ConductorSpecification" abstract="true">

<xs:complexContent>

<xs:extension base="vec:Specification">

<xs:sequence>

...

</xs:sequence>

<xs:assert test="CrossSectionArea">

<xs:annotation>

<xs:documentation xml:lang="en"> All conductors shall specify a cross section

area. The cross section area is an important parameter for numerous design

rules (e.g. aggregated cross section area of splices). </xs:documentation>

</xs:annotation>

</xs:assert>

<xs:assert test="CrossSectionArea/ValueComponent gt 0.0">

<xs:annotation>

<xs:documentation xml:lang="en"> A conductor with cross section area not greater

than 0 is non-existent. </xs:documentation>

</xs:annotation>

</xs:assert>

</xs:extension>

</xs:complexContent>

</xs:complexType>

...

Schema Filtering

The VEC is a comprehensive model with a variety of classes and attributes. In very few cases all of them are needed at the same time. For this reason it may be desirable to restrict the number of valid schema elements for specific interfaces. Schema Filtering can be useful in these cases.

For example, an interface for the exchange of UsageNodes would

only require a handful of VEC core classes. Another scenario might be that you

want to prohibit the use of CustomProperty in your own process.

Many scenarios are conceivable, in the core it always burns down to limiting the

power of the VEC purposefully to achieve a better controllability for certain

use cases and interfaces.

Since the scenario of Schema Filtering is more complex and less straight forward, than the Open Enumerations scenario, the following section just provides an idea for a possible approach and not a “ready-to-use” solution.

The basic idea here is, that an XSLT script simply removes all unnecessary elements and leaves the rest unchanged. You can use either a positive or negative filter approach. In our example, we use a negative filter list (all elements on the list are removed). When removing a class it is not sufficient to only remove the class itself. All usages of the class must be removed as well. A class that has mandatory usages by other classes, can not be removed unless all usages are removed recursively till an optional point is reached.

The file vec-tailor-schema.xsl

contains an example on how to remove the Transformation2D from the VEC scheme.

The following snippet shows the relevant parts only. The rest of the XSLT script

is known known as

identity transformation

(copy of the source into the destination without changes).

The first line removes the class itself. The second line removes all optional

attributes with the type Transformation2D. If you validate the resulting

schema you can easily check if the Transformation2D has any mandatory usage

that have been overlooked (it has not).

...

<xsl:template match="xs:complexType[@name='Transformation2D']" />

<xsl:template match="xs:element[@type='vec:Transformation2D' and @minOccurs=0]" />

...

Unfortunately IDREF attributes cannot be handled in this fashion

automatically, but have to be checked manually. The figure on the right side

displays the occurrenceOrUsage association between

OccurrenceOrUsageViewItem2D and

OccurrenceOrUsage. Associations are translated into IDREF or

IDREFS in the XML Schema, in contrast to aggregations that are translated into

contained xs:element.

The XML Schema representation of the association is the following:

<xs:complexType name="OccurrenceOrUsageViewItem2D">

<xs:complexContent>

<xs:extension base="vec:ExtendableElement">

<xs:sequence>

...

<xs:element name="OccurrenceOrUsage" type="xs:IDREFS" minOccurs="0"/>

...

</xs:sequence>

</xs:extension>

</xs:complexContent>

</xs:complexType>

That means a filtering rule cannot be formulated based on the target type of the association, as this type unknown in the XSD (in contrast to contained elements). Therefore a filtering rule must be more specific by explicitly addressing each relevant association, like this:

...

<xsl:template match="xs:element[@name='OccurrenceOrUsage' and

ancestor::xs:complexType[@name='OccurrenceOrUsageViewItem2D']]" />

...

Note: Make sure that the resulting schema remains compatible with the standard (XML Schema and Model Specification):

- Do not remove elements that are mandatory!

- Take extra care of usages via

IDREFassociations. These have to be checked in the model since the XML Schema is typeless for those associations.

Extension of open enumerations is perfectly valid as long as you adhere to the rules mentioned in the recommendation. ↩︎

Files, Partitioning, Sizing & Packaging (XML)

VEC XML Files

In general, XML data is structured in individual units of information, kown as documents. These documents can be transmitted through various machanisms, such as Web Services, enabling seamless exchange between systems. Alternatively, they can be stored within a file system for persistent storage or later retrieval.

This guideline gives best practices for the Partitioning and Sizing of such documents and explains how set of files can be exchanged together as a consistent archive (VEC-Package)

.vec and the Media Type application/vec+xml. Check out the IANA Media Types registry for further details: https://www.iana.org/assignments/media-types/application/vec+xmlPartitioning and Sizing

In theory it is possible to export all data of a company that relates to the vehicle network in a single VEC XML file. However, this is not a very reasonable approach for several reasons. Amongst those are:

- Intellectual Property Protection: For everything that is contained in a single VEC file, the “All or Nothing Principle” applies and it is hard or impossible to enforce a “Need to Know”. A recipient of a file, who requires only a single detail, always receives the complete information.

- Partial Changes: Even if only a single content element is changed, the complete file must be created and read, because only after reading the complete file the recipient knows which elements have changed.

- Tool Support: Tools must support large areas of the VEC in their Import- / Export interfaces, even if the areas do not belong to their use case.

- Technical Feasibility: If all information is contained in a single VEC file, the file itself can become huge, which places new requirements on the creating and reading tools (e.g. required memory).

Therefore, the general recommendation is to make a VEC files as small as possible and as large as necessary. The correct scoping of a generated VEC file depends on the use case of the information and the intended interface. Scoping means in this context the process of defining which information shall be bundled together in a single file for data exchange.

The following paragraphs contain guidelines for the decision, whether some information shall be packaged together or not:

- If the elements specified with the VEC are described, published and changed independently from each other regarding time and content, then they shall be placed in separate files (unit of publication). For example, this is the case for the description of harness components (connectors, wires etc.), represented by a part number. This rule applies only for the publication as master information from the original source of information. If the information is used to create other information, it can be embedded in a single file. For example, the description (complete or partial) of the used harness components will be embedded in the VEC describing a harness.

- If elements specified with the VEC have no relationships between each other (except reference base on PartVersions and DocumentVersions), then they shall be placed in separate files. For example, the specifications of a connector housing and a wire have no reference.

- If the relationship between two elements is indirectly over shared information, then this is no reason for the elements themselves to be placed in a single file (e.g. two connectors share the same CavitySpecification or two wires share the same CoreSpecification). If this piece of shared information is defined centrally, then it would have its own unit of publication, probably in its own DocumentVersion. In this case rule #1 can be applied. This means that, if the specification (e.g. a CoreSpecification) shall be exchanged, it shall be placed in its own VEC file. If the specification is used to describe another element (e.g. a wire) it shall be embedded in the VEC file of the described element. However, this is no reason to place all elements using this information in the same VEC file.

VEC Package

Background

A Vehicle Electric Container (VEC) in XML representation is a single XML file, following the structure defined in the VEC XML schema. It contains information about a harness, a set of harnesses, or other related information defined in the VEC specification. A VEC model can reference other documents via the DocumentVersion element and information contained in other files via the different “External References” concepts.

There are also good reasons for distributing information between multiple VEC files (see above Partitioning and Sizing of a VEC XML File)

However, there are use cases where one wants to exchange a VEC together with its external files and/or together with a set of somehow related VEC files. One use case for this is, for example, the exchange of a part master data library. The concept to do this, in the context of the VEC is called VEC-Package specifies how to exchange VEC files and any associated files as a single package.

Solution

A VEC-Package is an archive containing two things:

- One index file:

index.vec(a VEC file) - At least one data file (not required to be a VEC file)

The archive bundles all files together in a single file for exchange. Depending on individual technical requirements and preferences ZIP or GZIP can be used as archive formats. The compressed file can either contain the folder structure and content files of the VEC-Package directly (in case of ZIP), or it can contain a tar archive (in case of GZIP), with the folder structure and content files.

.vecpkg.{zip|gz}, depending on the used compression / archive format. The Media Type shall be application/vec-package+zip for ZIP archives and application/vec-package+gzip for gzipped tar archives. Check out the IANA Media Types registry for further details: https://www.iana.org/assignments/media-types/application/vec-package+zip and https://www.iana.org/assignments/media-types/application/vec-package+gzipIn addition, the archive can contain any number of addditional data files. There is no restriction on the type or format of these files. A VEC-Package may contain multiple VEC files and /or it may contain, for example drawings as SVG, CAD models of the harness or components as JT models.

The structure of the archive is not restricted. A VEC-Package may contain a flat set of files, but may also have a folder structure. It is recommended to use a folder structure to organize the files in the archive: e.g. to apply a grouping of all drawings or project related groupings.

There is no naming convention for files and folders inside the VEC-Package defined. It is up to the user to name a folder or a file. However, it is recommended to use the known and established file name extensions for the files in the package. I.e., .vec for a VEC file, .svg for a SVG file, or .jt for a JT file.

A VEC-Package shall contain an index file providing further information about the context of the package. The index file has the reserved name index.vec and it must be a valid VEC file, conforming to the VEC XML schema.

The elements of the index VEC file are restricted to the classes DocumentVersion and PartVersion. The index file contains a DocumentVersion for each file in the package. The attributes of the DocumentVersion are used to provide further information on the files:

- dataFormat: the format of the file in the VEC-Package (as Media Type if available).

- documentNumber: the number of the document

- documentVersion: the version of the document

- fileName: the name of the file as it appears in the package, including the folder structure. It must not point to any file location which is not part of the VEC-Package (e.g. a File on a central server file share). The fileName is relative to the VEC-Package root. It MUST NOT contain a drive or device letter, or a leading slash. All slashes MUST be forward slashes

/(UNIX-style).

A DocumentVersion may reference one or more PartVersion objects via referencedPart to give further details on the usage of the file. For example, the fact,

that an SVG file which represents the wiring diagram of a harness, can be expressed

in the index file by a DocumentVersion pointing to a PartVersion, which represents the

harness.

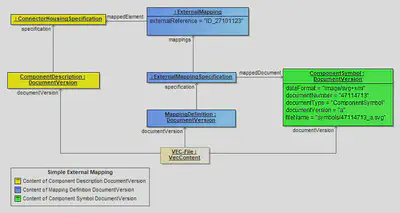

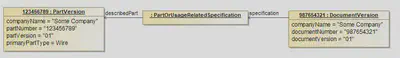

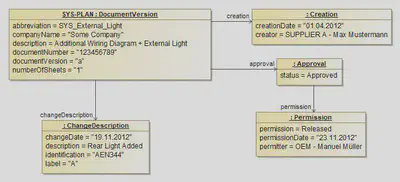

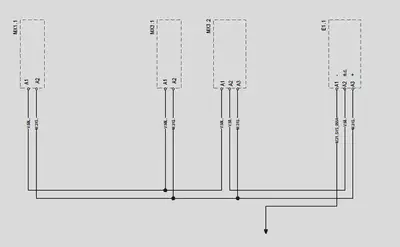

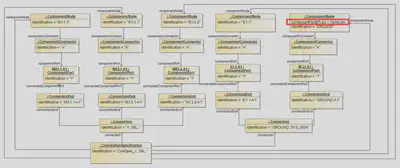

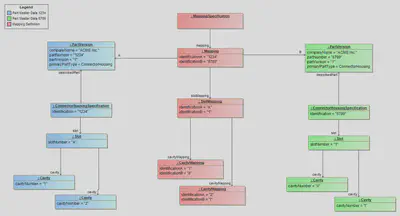

The figure above illustrates the structure of such a VEC-Package and the corresponding index.vec. The upper half of the diagram illustrates the file structure within the archive. In the root of the archive is the mandatory index.vec file that describes the content of the package. The content of index.vec is illustrated in the lower half of the diagram.

In the the example, the package consists of the following files:

index.vec: Describes the content of the package.- Information about a harness with the part number 4811 specified by:

drawings/4811_a.vec: A VEC file, containing the definition of the harness.drawings/4811_a.svg: A 2D SVG representation of the harness.

- Information about a connector housing (part number: 4711) specified by:

components/4711_a.vec: A VEC file containing the part master data of the connector.components/4711_a.svg: A component symbol (to be used in the 2D-drawing) defined in SVG.

In the VEC (especially in the index.vec) a DocumentVersion object is created for each external document (see lower half of the diagram). This DocumentVersion object references the PartVersion to which it is related.

RDF / OWL Representation

Various initiatives in the recent past have shown an increase in the importance of semantic models and the use of ontologies in industry (e.g. Catena-X). For this reason, and due to the opportunities and potential of this technology, it has been decided to also publish the VEC as an ontology in the future (starting in 2024). This should facilitate the creation of VEC-based solutions in the area of the Semantic Web / Linked Data / Knowledge Graphs and enable a simple transition between the different worlds.

The RDF variant of the VEC is intended as an additional technical representation of the underlying UML model, in addition to the XML schema variant that has existed since the beginning. This is not a replacement or discontinuation of the previous approach, but rather an extension of the toolbox for application scenarios in which the more monolithic representation as an XML structure appears less suitable (e.g. distributed development in dataspace / cloud architectures). Nevertheless, the XML variant will retain its raison d’être in the future for use cases in which a compact and complete representation is required (e.g. archiving or passing on defined development statuses).

Like the XML schema, the ontology and the associated SHACL schema are derived automatically and directly from the UML model of the VEC. This means that the model, the XML schema and the ontology should be consistent with each other at all times for a specific VEC version.

RDF Snippets

The following sections contain snippets of the transformation results. All excerpts are defined in RDF Turtle. The following namespace definitions are used:

@prefix : <http://www.prostep.org/ontologies/ecad/2024/03/vec#> .

@prefix owl: <http://www.w3.org/2002/07/owl#> .

@prefix rdf: <http://www.w3.org/1999/02/22-rdf-syntax-ns#> .

@prefix rdfs: <http://www.w3.org/2000/01/rdf-schema#> .

@prefix vec: <http://www.prostep.org/ontologies/ecad/2024/03/vec#> .

@prefix xs: <http://www.w3.org/2001/XMLSchema#> .

UML to OWL

VEC Namespace

The namespace of the VEC ontology is: http://www.prostep.org/ontologies/ecad/2024/03/vec#. The recommended namespace prefix is vec (used in the ECAD-WIKI for any example). The owl:versionIRI is http://www.prostep.org/ontologies/ecad/2024/03/vec/<version>#, e.g. http://www.prostep.org/ontologies/ecad/2024/03/vec/2.1.0# for every VEC version.

General

The following mapping rules apply to all elements:

- If a UML model element is mapped into RDF, the documentation in the model is mapped to

rdfs:comment. - Regardless of the pattern used to create the IRI of an element, the name of the element in the UML model is used as the

rdfs:label.

Classes

Regular classes in the UML Model (see figure below for an example form the VEC) are mapped to RDF in the following form.

- The name of the class is used as

IRI(within the VEC-namespace). - Class names begin with an upper case letter.

- The

rdf:typeisowl:Class. - Inheritance in the UML model is mapped to

rdfs:subClassOf.

For the class ItemVersion the mapping is the following.

vec:ItemVersion rdf:type owl:Class;

rdfs:comment "Abstract super-class for physical objects ..."@en;

rdfs:label "ItemVersion"@en;

rdfs:subClassOf vec:ExtendableElement .

Since the VEC uses a object oriented design concept multiple inheritance of classes is not allowed.

This is translated to owl:AllDisjointClasses statements for subclasses of a specific class.

[ rdf:type owl:AllDisjointClasses;

owl:members ( vec:DocumentVersion vec:PartVersion )

] .

Enumerations

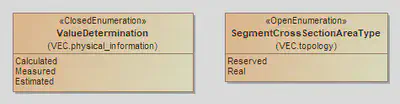

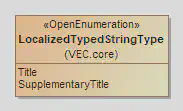

Enumerations are sets of predefined values. The VEC defines two concept for enumerations, Open and Closed enumerations (see Open and Closed Enumerations). You can find two examples in the figure below.

For the translation into RDF enumerations are treated as regular classes, in contrast to XML Schema, where an enumeration is just a xs:restriction on the xs:string datatype. To distinguish enumerations from regular VEC classes, the classes Enumeration, OpenEnumeration and ClosedEnumeration are explicitly defined in the ontology as follows (rdfs:comment and rdfs:label omitted).

vec:Enumeration rdf:type owl:Class .

vec:OpenEnumeration

rdf:type owl:Class;

rdfs:subClassOf vec:Enumeration .

vec:ClosedEnumeration

rdf:type owl:Class;

rdfs:subClassOf vec:Enumeration .

vec:enumLiteral

rdf:type owl:DatatypeProperty;

rdfs:domain vec:Enumeration;

rdfs:range xs:string;

rdfs:subPropertyOf rdfs:label .

The naming conventions for enumerations are the same as for regular classes. In addition, every Enumeration has a data property enumLiteral for the actual enum string value, as defined in the model. An enumeration in the UML model is translated to RDF as a subclass of OpenEnumeration or ClosedEnumeration. The Literals are translated as owl:NamedIndividuals of the class, the IRIs of the literals are created with the pattern: “<ClassName>_<LiteralName>”

vec:SegmentCrossSectionAreaType

rdf:type owl:Class;

rdfs:subClassOf vec:OpenEnumeration .

vec:SegmentCrossSectionAreaType_Reserved

rdf:type vec:SegmentCrossSectionAreaType , owl:NamedIndividiual;

vec:enumLiteral "Reserved" .

vec:SegmentCrossSectionAreaType_Real

rdf:type vec:SegmentCrossSectionAreaType , owl:NamedIndividiual;

vec:enumLiteral "Real" .

For OpenEnumerations the extension with new custom literals is straight forward. They can be easily defined as new individuals of the corresponding enum class. However, they should be defined in an appropriate namespace and not in VEC-namespace. The enumeration above could be extended for example like this:

acme:SegmentCrossSectionAreaType_MyCustomLiteral

rdf:type vec:SegmentCrossSectionAreaType , owl:NamedIndividiual;

vec:enumLiteral "MyCustomLiteral" .

In contrast to OpenEnumerations, ClosedEnumerations should not be extendable. Their set of enumeration values is predefined and closed. This semantic is expressed in the ontology representation by an equivalence axiom similar to the following:

vec:ValueDetermination

rdf:type owl:Class;

rdfs:subClassOf vec:ClosedEnumeration;

owl:equivalentClass [ rdf:type owl:Class;

owl:oneOf ( vec:ValueDetermination_Calculated vec:ValueDetermination_Measured vec:ValueDetermination_Estimated )

] .

Primitives

The UML Model uses several primitive datatypes. The mapping to XML Schema datatypes, which are also used as primitive datatypes in RDF is the following:

String=xs:string

Double=xs:double

Integer=xs:integer

Int=xs:integer

Boolean=xs:boolean

Date=xs:dateTime

Associations & Attributes

Remarks about IRIs for Associations & Attributes

The VEC UML model identifies attributes and associations by their role name (compare figure VEC UML Model - Classes above), for example abbreviation in the class ItemVersion or referencedPart in the class DocumentVersion. Those role names are only unique within the defining class and not in the entire model.

There are cases where two classes in VEC model define an attribute with the same name and both attributes have in fact the same semantic (e.g. Identification or aliasId). However, there are also multiple locations, where the same name is used for different semantics (e.g. CurrentInformation is used in some context as information about the maximum current, and in another context as information about the regular operating currents).

The following approaches were considered for IRI generation for properties, but rejected after careful consideration:

- Opaque Names, like p1243 are a common approach to this problem. However, support of such an approach would have been a major extension to VECs the existing modelling infrastructure, switching between the classic XML-based World and RDF would be significantly more difficult and human readability data would be significantly more limited, which in turn might compromise the acceptance of the RDF representation.

- Using Property Names alone. This approach would have been fine, if all property names are unique within the model or have exactly the same semantic. However, as this is not the case, this blurring would result in various problems. Starting for example with simple things like properties with the same name have different data types. Defining

rdfs:domain/rangestatements on those properties would lead to inconsistencies or contradictions. - Qualifying ambiguous property names only. Translation rules would depend on the model history. If a unique property gets a new “twin” at some point, qualification would be necessary. However, the former unique property must retain its name for stability / backwards compatibility. This would lead to an incomprehensible situation as to why which property is fully qualified and when and which is not.

The following mapping rules apply for attributes & associations:

- In order to have a general, context free and simple translation rule, that creates stable and reproducible IRIs for properties, the IRI is always fully qualified. It is created with the pattern: “

<ClassName><RoleName>” where first letter of<ClassName>is lower case and the first letter of<RoleName>is upper case. - All primitive properties are mapped to

owl:DataProperty, all other properties are mapped toowl:ObjectProperty. rdfs:range/domainstatements are created, corresponding to the declaring class and the datatype of the property.- All properties that represent a “containment” are mapped as

rdfs:subPropertyOf vec:contains(explained further down). Containments are all attributes and all associations modelled as composite.

vec:itemVersionCompanyName

rdf:type owl:DatatypeProperty;

rdfs:domain vec:ItemVersion;

rdfs:label "companyName"@en;

rdfs:range xs:string .

vec:itemVersionAbbreviation

rdf:type owl:ObjectProperty;

rdfs:domain vec:ItemVersion;

rdfs:label "abbreviation"@en;

rdfs:range vec:LocalizedString;

rdfs:subPropertyOf vec:contains .

To map the hierarchical structure of the VEC, two general properties are defined as follows:

vec:contains

rdf:type owl:ObjectProperty;

rdfs:comment "This is the representation of the containment modeled in the UML. All associations that are a \"containment\" in the UML model are subproperties of this property."@en;

rdfs:label "contains"@en .

vec:parent

rdf:type owl:ObjectProperty;

rdfs:comment "The inverse of 'contains'."@en;

rdfs:label "parent"@en;

owl:inverseOf vec:contains .

Ordered & Non-Unique

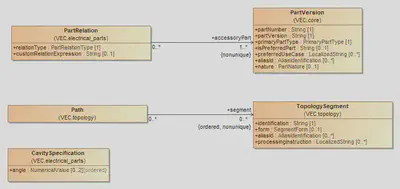

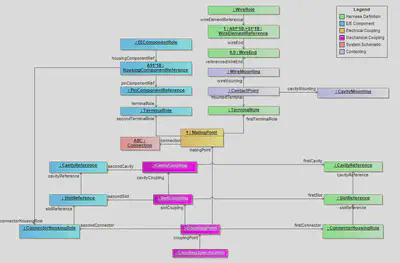

The VEC model allows attributes & compositions to Ordered and associations to Ordered and/or Non-Unique. See the figure below for the different cases.

Side Note: Non-Uniqueness is only possible for associations.

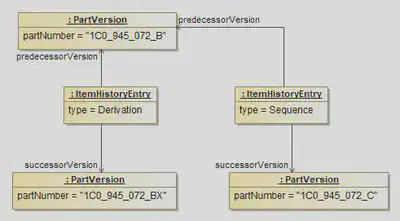

- Ordered means that the elements of the property / association have a specified order that has defined semantic in the domain. For example the order of the

TopologySegmentin aPathdefines the order in which a wire is routed through the topology. - Non-Unique means, that the same two element can be associated multiple times and that the number of associations is relevant.

Since RDF is a pure triple representation, there is no native way to represent order or non-uniqueness, in contrast to XML where all associations are ordered and non-unique per default. To represent these semantics in the VEC ontology additional model elements are introduced.

To express “order” as a general concept the class Ordered is defined as follows:

vec:Ordered

rdf:type owl:Class;

rdfs:comment "Class of elements that are ordered within their containment."@en;

rdfs:label "Ordered"@en .

vec:orderedIndex

rdf:type owl:DataProperty;

rdfs:comment "Defines the order of Ordered elements. Lower indices are further forward in a list. 0 is the lowest index, i.e. the first element."@en;

rdfs:domain vec:Ordered;

rdfs:range xs:nonNegativeInteger .

For all attributes & compositions order is defined within the context of the “container”. In consequence, there is only one order for each element, as there is only one container for each element. Therefore, the order can be “stored” in the element itself. In other words, all element that are contained in an ordered attribute or composition are also Ordered. In the ontology, this is expressed by the following triple:

vec:cavitySpecificationAngle

rdf:type owl:ObjectProperty;

rdfs:domain vec:CavitySpecification;

rdfs:label "angle"@en;

rdfs:range vec:NumericalValue , vec:Ordered;

rdfs:subPropertyOf vec:contains .

With associations, the same object can be referenced multiple times and receive different orders for each referencing.

For example, a segment can occur in different paths and in different places.

In these cases, a wrapper class is created in the ontology for the target class. The wrapper participates unambiguously in association in the context of the source object and references the actual target object.

This allows the non-unique semantics to be mapped. If ordering is also required, it is applied to the wrapper class, analogous to the mapping attributes and composition. For the Path / TopologySegment the resulting partial ontology is the following:

vec:pathSegment

rdf:type owl:ObjectProperty;

rdfs:domain vec:Path;

rdfs:label "segment"@en;

rdfs:range vec:TopologySegmentWrapper , vec:Ordered;

rdfs:subPropertyOf vec:contains .

vec:TopologySegmentWrapper

rdf:type owl:Class;

rdfs:comment "Container class for TopologySegment to participate in non-unique and/or ordered associations.".

vec:topologySegmentWrapperItem

rdf:type owl:ObjectProperty;

rdfs:comment "References the actual item for a Wrapper.";

rdfs:domain vec:TopologySegmentWrapper;

rdfs:range vec:TopologySegment .

UML to SHACL

In addition to the ontology, a SHACL schema is derived from the UML model to allow validation of RDF graphs similar to the classic XML schema.

Namespace

The namespace of the SHACL Shapes is http://www.prostep.org/ontologies/ecad/2024/03/vec-shacl# the recommended prefix is vecsh.

Classes

For each class a <ClassName>Shape is created, similar to the one listed below (shortened for readability). Constraints for cardinalities of associations and target types are generated.

vecsh:ItemVersionShape

rdf:type sh:NodeShape;

rdfs:subClassOf vecsh:ExtendableElementShape;

sh:property [ sh:class vec:CopyrightInformation;

sh:maxCount 1;

sh:minCount 0;

sh:path vec:itemVersionCopyrightInformation

];

#... more properties here ...

sh:property [ sh:datatype xs:string;

sh:maxCount 1;

sh:minCount 1;

sh:path vec:itemVersionCompanyName

];

sh:property [ sh:class vec:ChangeDescription;

sh:minCount 0;

sh:path vec:itemVersionChangeDescription

];

sh:targetClass vec:ItemVersion .

The constraints above ensure only the target types (objects) of the properties. Without additional constraints, a property could be used on any class as subject. To ensure that all properties are only used on the classes that declare the property in the UML model, for each class <ClassName>InverseShape is created, similar to the following one:

vecsh:ItemVersionInverseShape

rdf:type sh:NodeShape;

rdfs:subClassOf vecsh:ExtendableElementInverseShape;

sh:class vec:ItemVersion;

sh:targetSubjectsOf vec:itemVersionChangeDescription , vec:itemVersionCompanyName , vec:itemVersionCopyrightInformation

#... more properties here ...

.

Ordered / Non-Unique

For Ordered and Non-Unique attributes & associations the constraints are generated accordingly to the pattern described in the UML to OWL mapping section (see above).

vecsh:OrderedShape

rdf:type sh:NodeShape;

sh:property [ sh:datatype xs:nonNegativeInteger;

sh:maxCount 1;

sh:minCount 1;

sh:path vec:orderedIndex

];

sh:targetClass vec:Ordered .

vecsh:PathShape

rdf:type sh:NodeShape;

rdfs:subClassOf vecsh:ExtendableElementShape;

sh:property [ sh:class vec:Ordered , vec:TopologySegmentWrapper;

sh:minCount 0;

sh:path vec:pathSegment

];

sh:targetClass vec:Path .

vecsh:TopologySegmentWrapperShape

rdf:type sh:NodeShape;

sh:property [ sh:class vec:TopologySegment;

sh:maxCount 1;

sh:minCount 1;

sh:path vec:topologySegmentWrapperItem

];

sh:targetClass vec:TopologySegmentWrapper .

vecsh:CavitySpecificationShape

rdf:type sh:NodeShape;

rdfs:subClassOf vecsh:SpecificationShape;

sh:property [ sh:class vec:Ordered , vec:NumericalValue;

sh:maxCount 2;

sh:minCount 0;

sh:path vec:cavitySpecificationAngle

];

#... more properties here ...

sh:targetClass vec:CavitySpecification .

Enumerations

A general EnumerationShape is create to ensure that all enumerations define a vec:enumLiteral.

For each enumerations an individual <ClassName>EnumShape is created to ensure that only defined literals are used.

For OpenEnumerations the sh:severity of such “violations” is lowered to sh:Info since the addition of new literals is explicitly allowed, but custom literals should reported nevertheless.

vecsh:EnumerationShape

rdf:type sh:NodeShape;

sh:property [ sh:datatype xs:string;

sh:maxCount 1;

sh:minCount 1;

sh:path vec:enumLiteral

];

sh:targetClass vec:Enumeration .

vecsh:ValueDeterminationEnumShape

rdf:type sh:NodeShape;

sh:in ( vec:ValueDetermination_Calculated vec:ValueDetermination_Measured vec:ValueDetermination_Estimated );

sh:targetClass vec:ValueDetermination .

vecsh:SegmentCrossSectionAreaTypeEnumShape

rdf:type sh:NodeShape;

sh:in ( vec:SegmentCrossSectionAreaType_Reserved vec:SegmentCrossSectionAreaType_Real );

sh:severity sh:Info;

sh:targetClass vec:SegmentCrossSectionAreaType .

Handling of Identifiers

The VEC and its XML Schema offer different concepts for the identification of model elements addressing certain requirements and those shall be used accordingly.

Identification-Properties (VEC Model)

Many types defined in the VEC model have an “Identification” property (e.g. the OccurrenceOrUsage).

This is meant to be a semantic identifier of the object represented by the VEC element. The following rules apply to those identifiers:

- The expectations defined in the documentation of the VEC model of the corresponding attribute shall be ensured.

- The identifications shall be unique for a certain element type, at least within its context element. In other words, the VEC model and its representation as XML Schema is a hierarchical data model. That means, that an identification shall be at least unique within its direct parent element (e.g. the identification of a HousingComponent shall be unique within its EEComponentSpecification.

- Two elements of different types can have the same Identification. However, this is only recommended, when the two VEC elements represent the same domain entity from different points of view, otherwise this shall be avoided as far as possible.

- In general, it is recommended to keep the Identifications stable over the time. This means, that if an object is exported multiple times the Identification of it should be the same. However, this is not possible in all cases, for all processes and all tools. Therefore, a process and / or tool creating VEC files should describe for all elements, under which conditions Identifications are stable or new ones are created.

AliasIdentification-Properties (VEC Model)

Certain elements have the capability to define AliasIdentifications in addition to their

unique identifications. AliasIdentifications are scoped identifiers of the object. The scope can be a system, a company

or or process. One use case of this kind of ids is the creation of traceability links between different sources of information. Examples for usages of the AliasIdentifications are:

- The identifier of a connector in the electrological process (with geometric variants)

- The identifier of a node or segment in a MCAD tool

- An assigned UUID of an element.

id-Attributes (XML Representation)

All xs:complexType define an id-Attribute with the type xs:ID. These are technical ids

that are necessary for the referencing mechanism of the VEC within a single XML file.

The semantics, constraints and requirements are defined by the XML Standard and

XML Schema itself. These ids do not have any significance outside a VEC file.

See the Section id-Attibutes.

immutable-global-id-Attributes (XML Repesentation)

See the Section immutable-global-id-Attributes.

IRIs (RDF Representation)

In RDF all objects (named resources in RDF) require a global unique identifiers which is an IRI. This is mandatory for resource to be “referencable”.

The maturity of the IRI generation strategy decides quality & stability of links within RDF graphs. There it should be thoroughly thought through when representing VEC data in RDF.

The RDF IRI is very similiar to the immutable-global-id feature in VEC XML representations. When mapping VEC data from XML to RDF and back, it should be possible to use immutable-global-id (when defined), as RDF IRI and vice versa.

However, RDF IRIs are a standard concept defined in RDF, whereas the immutable-global-id are a specific feature of the VEC XML representation.

Extension Rules

If the well-defined data structures and fields are not sufficient for the specific needs of a process or a tool, the VEC provides powerful extension mechanisms. Namely the extension mechanisms are custom properties and open enumerations (see the corresponding chapters in the model description).

However, it should be considered that information transported via these mechanisms is not standardized and is always subject to an individual agreement between interface partners. Therefore, these mechanisms shall be used with extreme caution.

It is strictly forbidden to use these mechanisms for the transfer of information that is already standardized within the VEC. In particular it is not permitted:

- To store information in custom properties where already well-defined concepts exist in the VEC to store the same information, e.g. using a custom property instead of an attribute or a more specific class in inheritance tree.

- To use self-defined OpenEnumeration-literals when well-defined literals with the same semantics already exist.

VEC-Files that do not obey to these rules are noncompliant to this data format specification.

If the extension mechanisms are used, it shall always be considered if these extensions might be a valid feature request for the VEC Standard.

Type Inheritance

The VEC uses an object-oriented class and inheritance concept. The following clarifications apply to its use:

- Only non-abstract classes can be instantiated.

- In an inheritance hierarchy, the choice of the used type represents a semantic

information itself. For example, the usage of a

PluggableTerminalSpecificationis a more specific information than the usage of aTerminalSpecification. It is not required to use the more specific class if the information is not available or it should not be transmitted. However, it is not permitted to use the more general class and transfer the information of the more specific class in a custom property, or similar (e.g. use theTerminalSpecificationwith aCustomPropertytype=pluggable).

Default- and Missing-Value Handling

For various reasons, there may be attributes of entities where no value can be exported, or a special semantics is required. The cases are:

- The information is not supported by the system / process. So, it is never available for this system / process.

- The information is supported by the system; however, the value is not defined by the user.

- The information is explicitly defined as “arbitrary” for the use case (e.g. the part version in a bill of material or a compatibility statement).

All cases might exist for mandatory attributes as well as for optional attributes. Due to

the design, numerical values in the VEC and its high level of optionality the following

definition of special values should be only relevant for xs:string-Attributes:

| Mandatory Attribute | Optional Attribute | |

|---|---|---|

| Unsupported | <tag>/NULL</tag> | omitted tag |

| Undefined | <tag></tag> | <tag></tag> |

| Arbitrary | <tag>/ANY</tag> | <tag>/ANY</tag> |

/NULL&/ANYmeans, that the attributes with the name “tag” in the VEC receive these values.<tag></tag>means, that an attribute with the name “tag” and an undefined value is represented in the VEC as an existing XML element with no value (no contained text() node).omitted tag: means the element tag for the attribute is not present in the VEC

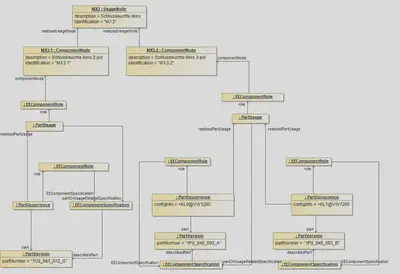

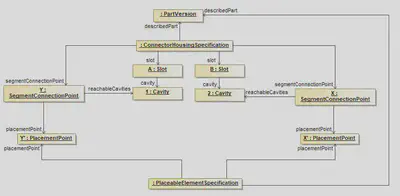

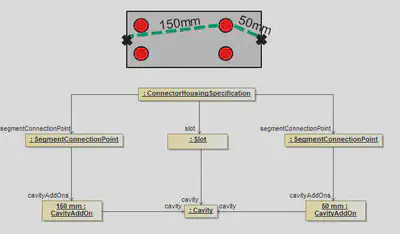

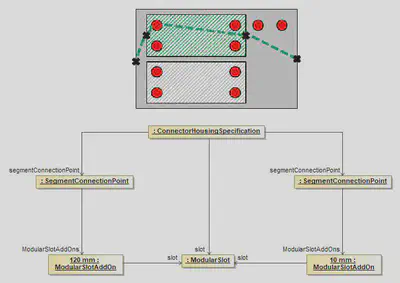

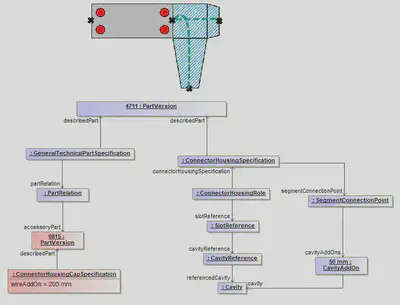

xs:double has less flexibility of allowed values. If the equivalent of /NULL is required for xs:double valued attributes, NaN shall be used. The other cases for xs:string-Attributes, mentioned above, are not supported by xs:double-Attributes.Instantiation of Model Structures

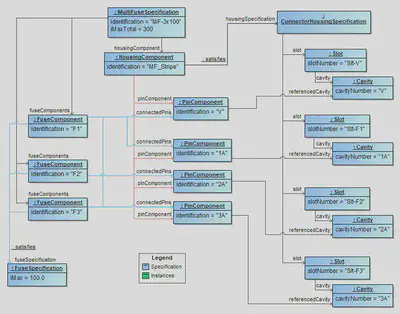

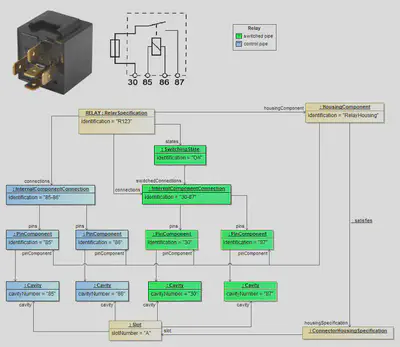

There are various locations in the VEC model where structures / patterns are defined

and used / instantiated somewhere else (e.g. a connector with its slots and cavities).

In most cases, the elements in the definition of a structure have corresponding

elements in the instancing (e.g. ConnectorHousingSpecification →

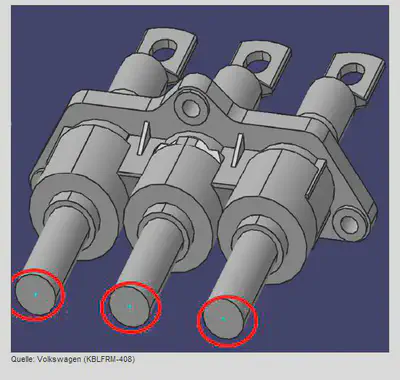

ConnectorHousingRole, Slot → SlotReference & Cavity → CavityReference).

In cases where defined structures are instantiated, these structures shall be

instantiated completely. That means, for every element in the structural definition a

corresponding element in the instancing shall exist, regardless if it is used in the

respective VEC or not (e.g. for each Cavity of a ConnectorHousingSpecification, a

CavityReference in the corresponding ConnectorHousingRole shall exist). This applies

to the following list of structures, which is here for reasons of clarification and which is

not exhaustive:

- Connectors

- Wires

- EEComponents

- CompositeParts (e.g. Assemblies or Modules)

Expected Behaviour of VEC Interfaces

A wide range of different systems, supporting different use cases, are used in the process of wiring harness development. All of them might have a VEC-Interface for input & output, so sooner or later the question arises “What are the expectations for the behavior of those interfaces?”. This section will discuss this question.

Background

In a document based data exchange scenario (e.g. working with a word processor) the intuitive expectation is, that a document / file is “opened”, changes are performed and the document is “saved” again, with the document now containing the original content plus the modifications.

However, this simple and intuitive approach is not feasible in a model based data exchange scenario like the one for the VEC. The VEC is not intended to be a file-based database that contains all information about a vehicle network, which grows continuously over the time (like a Word document or an ODT file of a book). The basic idea of the VEC is, to provide a consistent language (model) for data exchange in the process of wiring harness development and to allow the exchange of use case specific slices of information within the process between systems and organizations.

This fundamental concept means that there is no such thing as “the one VEC interface”. The important question is, which use cases (or slices) of the VEC data model are supported or required for a specific interface.

Let’s assume that in our system landscape one component is responsible for the synthesis of electrology and geometry, and the derivation of a wiring harness from it. Such a system would potentially have 4 interfaces requiring different sections of the VEC model:

- Topology (IN)

- System or Wiring Schematic (IN)

- Part Master / Component Data (IN)

- Harness Definition (OUT)

In addition, the scope and validity of the different information slices may vary. For example, component data could be updated daily, with only the changed components at a time, but with a global validity, while a wiring harness definition is only valid for a specific vehicle context.

Even when considering only this example, it is already obvious that it does not make any sense to formulate requirements on cross-relationships between imported and generated VEC data, like “a system has to be able write all VEC data it has imported in an unchanged matter”.

Content of a VEC

A VEC can contain any scope, amount and combination of information that is valid, with respect to the VEC Model and the Implementation Guidelines. There shall be no requirement to create VECs with restricted content specifically for importing / receiving systems.

A receiving system shall be able to accept any valid VEC. If the VEC contains more than the required information of the system, the system is free to ignore the pieces of information irrelevant for its purpose. It does not have to store the ignored pieces for a later reexport. However, it shall not refuse the import of a VEC because of “too much” information.

On the other hand, it is up to the system to verify that a VEC contains enough information for the use case of the system. If that is not the case, the system can reject the import because of “too little” information.

Traceability Scenarios

Even though it is not possible to define general relationship requirements between imported and exported data, there are use cases in which a traceability between imported and exported data is required. In such cases, slices of imported data might be embedded into the exported data. This scenario is described in section “Combination and Reuse of Documents”

Summary of the Requirements

The aforementioned results in the following general requirements for systems with VEC interface:

- A system is not required to interpret, implement or store the full extent of the VEC model, when only portion of it is required for its specific use case.

- A system must be able to extract the information relevant for its use case from VEC files that contain more information than the system itself requires or is able to process.

- A system is only required to export the information relevant to its use case. In other word, in a roundtrip scenario with a “more powerful” system it may return less than it has received.

- On the other side, a system that is able to export a very extensive VEC is not required to strip the information down for a “less powerful” system.

- A system can reject VEC files that do not contain enough or only irrelevant information for its use case.

Key Concepts

External References

For reasons of traceability (e.g. requirements) or because certain information is better represented in other standards than in the VEC format (e.g. 3D models for components), it is necessary to be able to reference external documents from VEC elements. This guideline describes how these external documents can be addressed and what concepts exist to connect those documents with VEC model elements (and when to use which).

Referencing an external Document

As described in the Implementation Guideline “General Structure” the DocumentVersion serves several purposes, one of which is the referencing of external Documents. So, whenever a connection between a VEC element and an external document should be created, a DocumentVersion is required to address the document. Such a DocumentVersion should contain no payload data (Specification). However, it contains the same meta-data as it would, when included as a full featured document (e.g. DocumentType).

index.vec file consists practically only of such external references, as described in the recommendation Chapter “VEC-Packgage” and in the corresponding Implementation Guideline.There are different possibilities to resolve such a reference and retrieve the actual document:

- PDM reference with Domain Key: Per definition, a document version is unambiguously identified with its DocumentNumber, DocumentVersion and CompanyName. With context knowledge about the process, the document can be resolved in the corresponding PDM / Document Management System.

- FileName: If the document is packaged together with VEC file (VEC Package) the filename attribute of

DocumentVersioncan point to a location within the VEC Package. If the document is not part of the VEC Package, the FileName-Attribute shall be omitted. - Location: If the document can be resolved outside the VEC package, the Location-Attribute can point to a location (via an URN or URL) where the document can be resolved. For files that are stored following a specific procedure or systematics (e.g. in PDM System) the usage of URNs should be the preferred way. This decouples the referencing from a concrete physical location, which might be different in different contexts or might be changed over the time.

Connecting VEC Model Elements

After defining an external reference as DocumentVersion there are multiple approaches to create connections to VEC model elements. Some approaches have a specific semantic, some are more generic. The different possibilities are summarized below. If there are more than one possibility for a specific element, you have to choose the one with most specific semantics.

DocumentVersion.ReferencedPart →PartVersion: The document describes the part in some way (e.g. a component drawing). See “Parts, Documents and Resources”.DocumentVersion.RelatedDocument: The association is an informative link which DocumentVersion are related to each other (e.g. by derivation, A Harness-Drawing is related to a 3D-Model). See “Parts, Documents and Resources”.RequirementsConformanceStatement.DocumentVersion: SomePartVersions are satisfying (or not) the requirements defined in the external document. See “Conformance to Requirements”.ExternalMappingSpecification.MappedDocument: The external document is a different view on the same content described by this specific VEC and a mapping / active linking between the same elements in both views should be created. For example a harness and its drawing in SVG. See “External Mapping”.DocumentBasedInstruction.ReferencedDocument: AnOccurrenceOrUsagehas specific installation instructions that are defined in an external document (e.g. a manual or a working specification). See “Installation Instructions”.ExtendableElement.ReferencedExternalDocuments: The referenced document contains additional information about the VEC element, that cannot be represented in the VEC in an appropriate way. See “Parts, Documents and Resources”.DocumentRelatedAssignmentGroup.RelatedDocumentVersion: ADocumentRelatedAssignmentGroupallows the creation of traceability links to elements in aDocumentVersionfor a set of VEC objects. The semantic of the traceability link is defined by theDocumentRelationType, for example requirements that apply to these VEC elements. See “Assignment Group”.

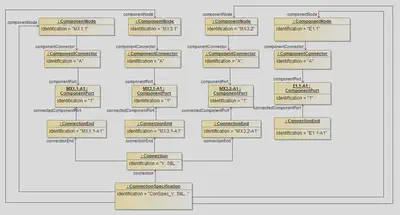

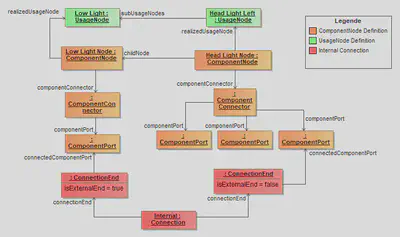

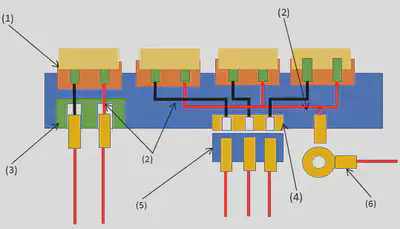

External Mapping

The diagram above shows the usage of the external mapping mechanism. The elements highlighted in yellow represent the actual information described by this VEC instance. The elements highlighted in blue are defining the mapping itself and the DocumentVersion highlighted in green represents the link to the mapped document (in this case a SVG-symbol).

The ExternalMapping in this example defines that a representation of the referenced ConnectorHousingSpecification can be found in the SVG-symbol under the key ID_27101123. This is especially useful, if one wants address specific subelements (e.g. for highlighting). In the example, the Cavitys of the connector could also be mapped to specific symbols within the SVG.

The actual content data of the VEC-file (highlighted in yellow) and the mapping information is separated into two different DocumentVersion elements. This means even though both information are contained in the same VEC-file, from the perspective of a versioning mechanism they are clearly separated.

External Installation Instructions

The usage of file-based installation instructions is quite similar to the described approach for external documents. The FileBasedInstruction defines a pointer to the file packaged together with the VEC-file in the container and is referenced by the PartOccurrence.

The same effect could be achieved if a DocumentBasedInstruction is used, pointing to an external document (defined as described in the section before).

Important: The difference between the two approaches is that for the DocumentBasedInstruction a DocumentVersion is required. This means that the external file must be an official document with a document number, an appropriate versioning and so on. The FileBasedInstruction can point to any file needed (within a VEC package).

It is forbidden to use the FileBasedInstruction approach, if the external file is a valid document.

General Structure of VEC Files & Documents

The VEC has two major key concepts: PartVersion and

DocumentVersion. Both are ItemVersions and

both are used to reference / identify a piece of relevant information in a PDM

context unambigiously.

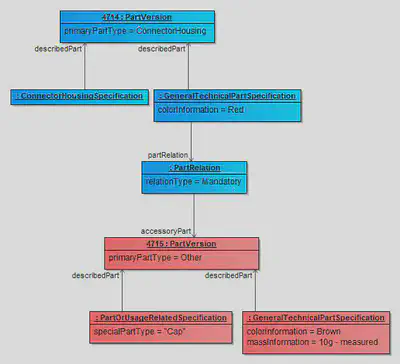

Whereas the PartVersion “just” represents a PDM anchor /